6:00 AM Start of the day.

Rain or shine or snow; the oven needs to be fired up first thing in the morning and heated for about 4 hours. You can read a detailed account in the Oven Management section.

Actually though the day's bake starts the night before. That's when we mix our leavens for the breads we will be doing. The leavens can account for as much as 30% of the total weight of the batch that we are doing. We generally do 3 or 4 different types of bread each day. Each type of bread requires a different leaven, thus there are that many leavens fermenting over night. |

There are many factors that control how the day's bake is going to progress, many of them out of our control.

Certainly one of the big ones is the season; in winter everything works slower. If it's a real cold day the bakery is cool and the breads raise slower which means we need to start somewhat earlier. Fortunately our leavens like it cool, around 70 C.

If the wind is blowing strongly from the north then the oven is harder to get started and slower to heat.

Each of our breads behave slightly differently so we need to group them together so they work well together and don't rush our schedule. Our sandwich bread, the only one we do in pans, rises slowly and so we start it early. The light rye is relatively quick so it is started later and will still likely be ready for the oven before the sandwich bread.

The flour that we use is freshly ground and its moisture content will vary. In the fall the grain can almost literally come straight from the field to the mill and then to us within a couple of days. We buy our flour from a farmer who has a stone mill and I find it very cool that I can point to the fields where your bread came from.

Certainly one of the big ones is the season; in winter everything works slower. If it's a real cold day the bakery is cool and the breads raise slower which means we need to start somewhat earlier. Fortunately our leavens like it cool, around 70 C.

If the wind is blowing strongly from the north then the oven is harder to get started and slower to heat.

Each of our breads behave slightly differently so we need to group them together so they work well together and don't rush our schedule. Our sandwich bread, the only one we do in pans, rises slowly and so we start it early. The light rye is relatively quick so it is started later and will still likely be ready for the oven before the sandwich bread.

The flour that we use is freshly ground and its moisture content will vary. In the fall the grain can almost literally come straight from the field to the mill and then to us within a couple of days. We buy our flour from a farmer who has a stone mill and I find it very cool that I can point to the fields where your bread came from.

The night before:

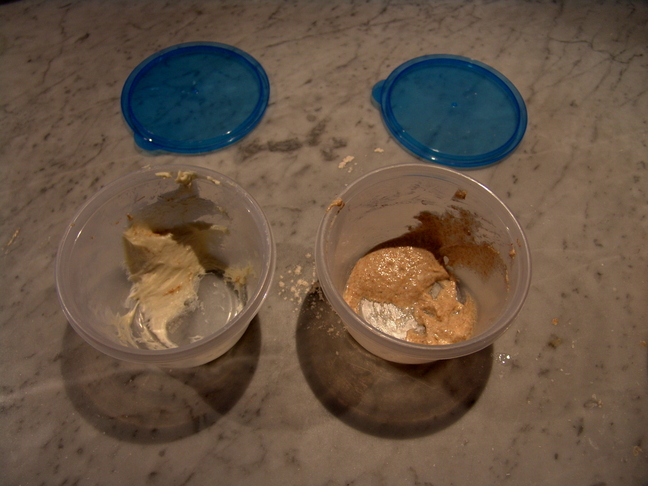

As mentioned above today's bake started the night before with the preparation of the leavens for the breads that I'll be baking. On the right is our leaven (actually at this stage it's called a "chef" ), having fermented all day and ready to help create the leavens for each bread.

Below is the remainder of the chefs, once I've used what I need. I will feed them and let them ferment overnight for the following day's bake. In the picture, on the left, is the all purpose flour chef and on the right is our whole wheat leaven. |

All set of the next day's bake:

This is about 7pm the evening before and I've decided to make 3 types of bread (6 loaves of each). On the left is the leaven and soaking grains for our Grain bread. In the middle we have the leaven for Hippy bread as well as wheat berries soaking and hemp hearts weighed out. On the right is our Raisin bread leaven and raisins. In the foreground we have the original chefs, feed and read to bed down for the night. Our chefs are like house pets, needing to be carefully looked after, kept warm and fed and watered twice a day.

About 8:00 am- Mixing and waiting:

So, while the fire is burning, we can start mixing up the breads. In this case we'll follow the grain bread and as you can see on the right our grain leaven has worked well over night and is nice a bubbly. We mix this up with the combination of grains and two types of flour; a fine ground flour and red fife whole wheat. Just a reminder that I'm making 6 loaves of grain bread today and the image below shows the mixer put together and is then left to work for 1/2 hour. This step is called an "autolyse".

|

Autolyse:

There are a couple of key points regarding this rest stage. It provides time for the ingredients to absorb the water. Even though it is thoroughly mixed and feels wet the flour has not actually absorbed the water yet.

The other very important point is that there is no salt in the mixture yet. This to allow the gluten to work up with the leaven without the influence of salt. The salt we add isn't for flavour, it is to strength the gluten strands. If the salt is put in too early the gluten becomes stiff and harder to stretch out. |

Not your grandmother's kneading:

Once the autolyse is complete I begin to knead the dough. This is reasonably moist dough and won't handle the way you might be familiar with, being very sticky. The technique that I'm using is nice and gentle and allows me to draw out the gluten strands.

This is also when the salt is added. I'll work the dough for about 5 minutes and then let it ferment for an hour then pull it out and gently stretch it to further develop the structure. I'll do that twice. |

|

|

Once the dough has been fermenting for an hour it is time to pull it out of the bowl and stretch it. This is a very straightforward process and the only thing to pay attention to is to stretch the whole batch, aiming to have the dough more or less the same thickness. The aim is also not to stretch so much that it puts holes in the dough, breaking the gluten strands. Folding it back together also helps since it puts a bit of tension on the dough thus adding more stretch.

|

|

|

|

Another hours has passed and we again want to stretch the dough. You may notice in the video that the dough is tighter and easier to handle.

|

|

The oven has been burning for about 4 hours now and it is time to pull the remaining coals and wash the hearth.

While the clean oven doesn't look like much the inside is over 800 F. On this day I've washed out the oven at about 11am. It will be 3pm before the oven is cool enough to put bread in (at about 580 F). So the bread needs to be ready about then. |

Shaping loaves:

Between mixing, autolyse, kneading and stretching about 4 hours have passed. I've weighed and roughly shaped each loaf and they've rested for about 10 min. and now it's time to shape the dough into loaves. The loaves then go onto couching clothes to do a final proof before going into the oven. Today, being that it's not quite spring, the proof will be about 2 1/2 hours. I'll be watching the bread to make sure it doesn't over proof and go flat.

On the right is a video showing how I shape the loaves. Keep in mind I'm doing 3 different breads this day. By the time I am working on shaping the grain bread I've already done the raisin bread and I'll do the hippy after the grain. I'm also preparing cranberry scones, peanut butter cookies and pies. There's no idle time, and I clean as I go. I hate having to clean dishes and pans at the end of the day. |

|

In the oven:

Just over 2 hours have passed from when I shaped the grain loaves and the bread is ready. I've gauged it well and all three breads are ready at the same time.

At the far right is the grain just going in the oven. The slashes on top are to allow for oven spring, which is the expansion of the bread as it cooks. If we didn't put the slashes in the loaves would burst wherever there was a weak spot. An important aspect of managing loaves in the oven is steam. As soon as all the bread is in the oven, and that should be done as quickly as possible, I spray the oven with water to generate steam. Two main reasons are to keep the top of the loaves moist and allow the spring; but also to help brown the surface of the bread by the Maillard reaction. http://en.wikipedia.org/wiki/Maillard_reaction |

Cranberry Scones:

While the bread is in the oven I need to get the cranberry scones mixed, weighed and on the pan ready when the bread comes out.

Our scones are very popular. The below three images show the scones being put together. The key to a good scone is to mix only till the ingredients hold together and absolutely no more. One thing most people miss and thus tend to over mix, is that as you handle the scone mixture for weighing and shaping you are still mixing the dough. |

MMMMMhhh!

So the bread took about 30 minutes to cook. I put the bread in while the hearth was reading about 560 F. I use the laser thermometer to check it.

At left you can see the bread got a nice spring, with the hippy bread in the foreground, raisin in the middle and the grain at the far end. With this load of bread and the firing I did the oven has cooled down by about 100 F. It will regain some of that heat but I don't need it any hotter for the rest of the bake. |

Once the bread is out the scones go in next, then the pies and last cookies.

Each load takes some heat out of the oven and I schedule the different batches based on how hot the oven needs to be. Scones like a reasonably hot oven as do the pies; although not as hot as the bread. Cookies need a much cooler oven. A good rule of thumb to go by is, the more sugar in the product the lower the temperature should be. |

The day is not over.

So, the bake went well today and now it's time to clean up and setup for the next day's bake. There's also enough heat left in the oven to cook supper.